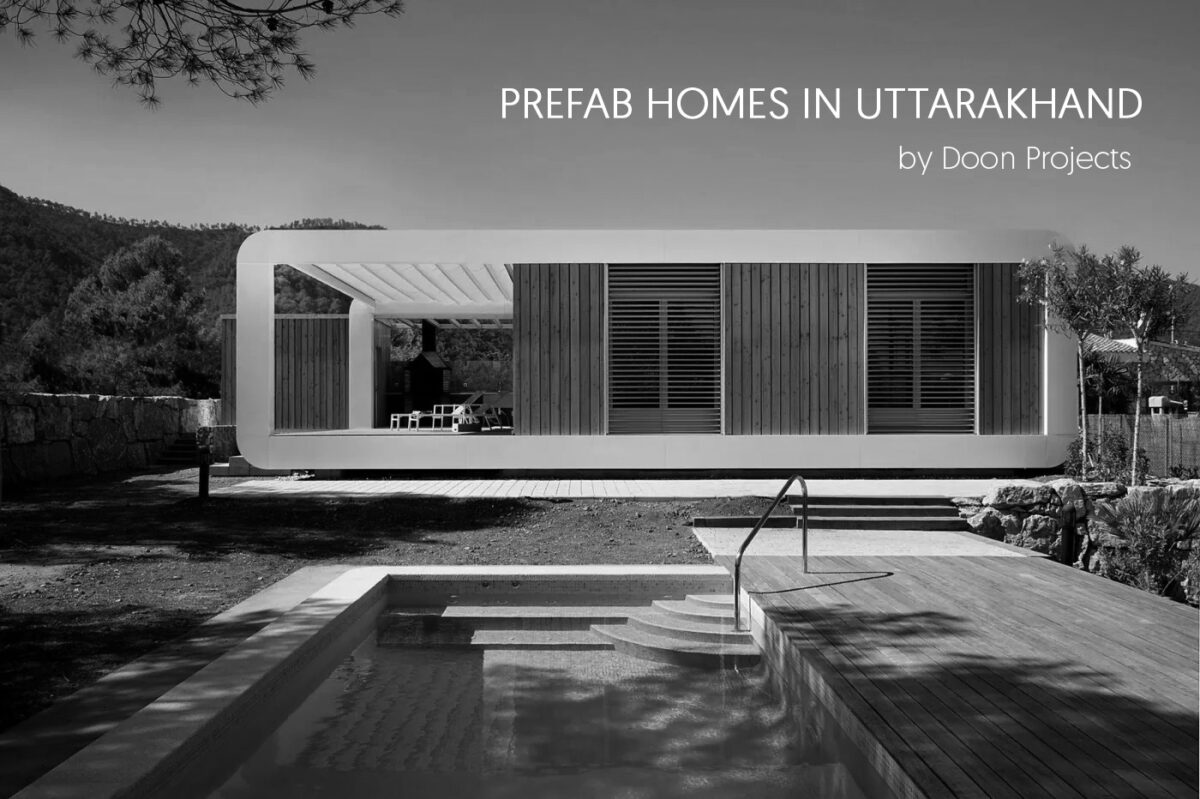

Doon Projects – Interior Designer and Construction company in Dehradun. Doon Projects Design & Construction, one of Uttrakhand’s most reputable companies, provides exceptional interior design and construction services. Based in Dehradun, Uttrakhand, India, the company has been working proactively to deliver quality projects. The range of services extends from customized furniture to ceiling, modular kitchens, wall paneling, and front facade design. Whatever the problem, the company has all the solutions.

Ever heard of Prefabrication? If not, this article will help you learn everything you need to know.

What is Prefabrication?

Prefabrication is when all the structure parts are collected and arranged offsite in a manufacturing unit or a factory. Once fully assembled, these prefabricated assemblies and sub-assemblies are transported to the construction site, where the structure is to be built.

About Prefabricated Structures

In modern building practices, prefabricated structures are a boon. Compared to conventionally constructed structures, they save a tremendous amount of time, money, and materials.

Traditional construction methods require transporting materials such as bricks, stones, timber, cement, sand, steel, construction aggregate, etc., to the site. While in Prefabrication, only the foundations are built on-site, and all other components, such as wall sections, roofs, and floors, are made in a factory and bolted together on site. Prefabricated units are not limited to building construction and architecture but are also used extensively in the interior. It includes doors, windows, stairs, wall panels, floor panels, partitions, roof trusses, and entire buildings.

Benefits of Prefabrication

Before construction, we certainly think about many things, including gathering resources, labor, materials, etc. All of these factors can be pretty tiresome for you to manage. The most famous building technique today, Prefabrication, saves you the hassle of building from scratch. Besides being one of the most innovative construction methods, it has several other benefits, such as:

- It is often less expensive to move sub-assemblies out of a factory than to move pre-produced resources to each location.

- Provisioning resources on site can result in additional costs; the Prefabrication of assemblies can save costs by reducing the work on site.

- Prefabrication minimizes the need to deploy many skilled workers to the site.

- Using factory tools such as cranes, jigs, conveyors, hydraulic testers, shake tables, etc., results in faster, more accurate, and higher quality production.

- Indoor factory environments help eliminate the most restrictive conditions, such as lack of water, power, exposure to a hazardous environment, and weather’s effects on production.

- Factory production also promotes hassle-free, healthier, and safe construction practices.

Materials Used in Prefabrication

It is a myth that Prefab structures are made out of poor-quality materials. Prefabrication involves using the same materials as used in traditional building practices innovatively. Here is a list of some of the most widely used materials:

- Concrete

- Steel

- Wood

- Glass

- Recycled and reclaimed materials

With the help of the materials mentioned above, any component such as panels, roofs, walls, columns, beams, blocks, etc., can be manufactured. The only difference is that they are pre-casted.

Installation (brief)

The installation process of prefabricated structures is comparatively less complicated. It involves a few simple steps, namely:

1. Casting:

It involves preparing precast structure parts in various shapes and sizes according to the requirements. E.g., For example, cement concrete is poured into a mold of the desired shape, and later a vibrator is used to avoid lumps, unwanted lines, or honeycombs inside. Wood panels are pre-casted using different tools, machines, and techniques.

2. Curing:

The casted components are further cured into a casting container. This ensures that the cement is adequately hydrated, controls moisture, humidity controlled, and a conducive temperature is maintained in cement concrete slabs. For various other materials, steps are taken accordingly.

3. Transportation:

After completion, all prefabricated parts are loaded onto large trucks and transported to the construction site.

4. Erection:

It is a process in which all components are assembled on-site with the help of cranes and skilled workers.

Reasons for the Growing Demand for Prefabrication

Prefabrication has seen significant growth in the commercial and residential sectors in recent years due to rapid infrastructure development, population growth, and urbanization. These days, people prefer prefab structures as they are affordable, time-saving, highly sustainable, and energy-efficient. Prefab houses have positively influenced the market. In addition, prefabricated construction offers strength to the structures, allowing buildings to withstand earthquakes.

Further, a few additional factors contribute to the market’s growing demand for prefabricated structures, such as:

- Projects concerning the Mass Townships

- A rise in the demand for branded designers

- Rising opportunities in developing countries

- Market expansion for prefabricated homes

- Increased focus on the three pillars of profit, people, and planet

Uttarakhand and Prefabrication

Uttarakhand is one of the most beautiful states in India. Crossed by the great Himalayas, Uttarakhand is known for its scenic beauty, climate, food, fun-loving people, and serene environment. The State is all about balance; In addition to development, people also care about nature. The recent development in Uttarakhand has resulted in the destruction of many forests and the depletion of enormous resources.

Most Uttarakhand regions are mountainous, making it challenging to carry construction practices; deploying materials and labor can be a huge task. Weather conditions also lead to many other issues, such as delays in construction and wastage of materials. Prefabrication could play a crucial role in helping the State develop sustainably. As mentioned in the article, Prefab construction practices will result in less consumption and more output. If we opt for Prefabrication, it will save us a lot of hassle, time, and resources.

Conclusion:

In summary, it can be said that Prefabrication helps you to manage your project efficiently, cost-effectively, and sustainably. Also, modern building practices are likely to replace traditional building practices in the future. There are many reasons to choose prefab building practices for your home, and trust us when we say you won’t be disappointed. Contact a professional if you wish to avail prefabrication services. You can contact Doon Projects and Construction for areas in and around Uttarakhand.

Projects by Doon Projects and Construction

Doon Projects and Construction has done a considerable amount of work in Prefabrication. For better advancement in Uttarakhand, the company seeks to raise awareness and execute prefabricated projects.

Here’s a list of some of the most notable projects: Click here